中文

Русский

español

Revolutionizing Tote Bag Manufacturing - Automation and Robotics

Sep 23, 2024

Views:

232

|

Gahumi

Innovation in manufacturing processes has revolutionized various industries, and tote bag manufacturing is no exception. Automation and robotics have emerged as powerful tools in streamlining production, improving efficiency, and enhancing the overall quality of tote bags. This article explores the impact of automation and robotics in tote bag manufacturing, highlighting the benefits, challenges, and future prospects. We will delve into the role of automation in cutting and sewing processes, the integration of robotics in assembly and packaging, and the collaboration between technology and human craftsmanship. By understanding the revolution in tote bag manufacturing, businesses can leverage automation and robotics to meet the growing demand for custom tote bags with increased efficiency and precision.

1. Automation in Cutting and Sewing Processes

Automation has significantly transformed the cutting and sewing processes in tote bag manufacturing. Computer Numerical Control (CNC) machines and computerized cutting systems have replaced manual cutting, ensuring precision and consistency in fabric cutting. These automated systems can handle multiple layers of fabric simultaneously, reducing material waste and increasing production speed. In the sewing process, automated sewing machines have improved efficiency and accuracy, reducing human error and ensuring consistent stitch quality. Automation in cutting and sewing processes not only saves time and labor costs but also enhances the overall quality and durability of tote bags.

2. Robotics in Assembly and Packaging

Robotics has found its way into tote bag assembly and packaging, further revolutionizing manufacturing processes. Collaborative robots, or cobots, work alongside human operators in tote bag assembly, performing repetitive tasks with precision and speed. These robots can handle various assembly processes, such as attaching handles, zippers, or closures, ensuring consistency and reducing the risk of errors. Additionally, robots are used in tote bag packaging, efficiently stacking and organizing finished products for shipment. Robotics in assembly and packaging not only improves productivity but also enhances worker safety by automating repetitive and physically demanding tasks.

3. Benefits of Automation and Robotics

The integration of automation and robotics in tote bag manufacturing offers several benefits. Firstly, it improves production efficiency, reducing manufacturing lead times and increasing output capacity. Automation and robotics also enhance product consistency and quality, minimizing human error and variations in the manufacturing process. Additionally, these technologies can handle complex designs and customization requirements with ease, allowing for the production of custom tote bags at a faster pace. Furthermore, automation and robotics contribute to cost savings by reducing labor costs and material waste. Overall, the adoption of automation and robotics in tote bag manufacturing improves productivity, quality, and cost-effectiveness.

4. Challenges and Considerations

While automation and robotics offer significant advantages, there are challenges and considerations to be addressed in tote bag manufacturing. Initial investment costs can be high, requiring businesses to carefully evaluate the return on investment. Additionally, the implementation of automation and robotics may require retraining or upskilling of the workforce to operate and maintain these technologies effectively. Ensuring compatibility between automated systems and existing manufacturing infrastructure is another consideration. Furthermore, the integration of automation and robotics should be balanced with the need for human craftsmanship and customization, as human touch and creativity play a vital role in tote bag design. Striking the right balance between automation and human involvement is crucial to maintain the integrity and uniqueness of custom tote bags.

5. Future Prospects and Industry Trends

The future of tote bag manufacturing lies in the continued development and integration of automation and robotics. Advancements in machine learning, artificial intelligence, and computer vision technologies will further enhance the capabilities of automated systems, enabling them to handle more complex tasks and adapt to changing production requirements. Industry trends also point towards increased customization and personalization options, and automation and robotics will play a key role in meeting these demands efficiently. Moreover, the integration of sustainability practices, such as the use of eco-friendly materials and energy-efficient technologies, will shape the future of automated tote bag manufacturing, aligning with the growing focus on environmental responsibility.

6. Collaboration between Technology and Human Craftsmanship

While automation and robotics bring efficiency and precision to tote bag manufacturing, the collaboration between technology and human craftsmanship remains essential. Human artisans possess the creativity, expertise, and attention to detail required for intricate designs, customization, and quality control. Tote bag manufacturers can leverage automation and robotics to streamline repetitive tasks, allowing artisans to focus on design, product development, and quality assurance. The combination of technology and human craftsmanship ensures that tote bags maintain their unique appeal and artisanal touch, while benefiting from the efficiency and consistency provided by automation and robotics.

Automation and robotics have revolutionized tote bag manufacturing, improving efficiency, productivity, and quality. From automated cutting and sewing processes to robotics in assembly and packaging, these technologies offer numerous benefits. While challenges and considerations exist, the future of tote bag manufacturing lies in the continued integration of automation and robotics. Striking a balance between technology and human craftsmanship is crucial to maintain the uniqueness and customization of tote bags. By embracing automation and robotics, businesses can meet the growing demand for custom tote bags while enhancing productivity, quality, and sustainability in the manufacturing process.

1. Automation in Cutting and Sewing Processes

Automation has significantly transformed the cutting and sewing processes in tote bag manufacturing. Computer Numerical Control (CNC) machines and computerized cutting systems have replaced manual cutting, ensuring precision and consistency in fabric cutting. These automated systems can handle multiple layers of fabric simultaneously, reducing material waste and increasing production speed. In the sewing process, automated sewing machines have improved efficiency and accuracy, reducing human error and ensuring consistent stitch quality. Automation in cutting and sewing processes not only saves time and labor costs but also enhances the overall quality and durability of tote bags.

2. Robotics in Assembly and Packaging

Robotics has found its way into tote bag assembly and packaging, further revolutionizing manufacturing processes. Collaborative robots, or cobots, work alongside human operators in tote bag assembly, performing repetitive tasks with precision and speed. These robots can handle various assembly processes, such as attaching handles, zippers, or closures, ensuring consistency and reducing the risk of errors. Additionally, robots are used in tote bag packaging, efficiently stacking and organizing finished products for shipment. Robotics in assembly and packaging not only improves productivity but also enhances worker safety by automating repetitive and physically demanding tasks.

3. Benefits of Automation and Robotics

The integration of automation and robotics in tote bag manufacturing offers several benefits. Firstly, it improves production efficiency, reducing manufacturing lead times and increasing output capacity. Automation and robotics also enhance product consistency and quality, minimizing human error and variations in the manufacturing process. Additionally, these technologies can handle complex designs and customization requirements with ease, allowing for the production of custom tote bags at a faster pace. Furthermore, automation and robotics contribute to cost savings by reducing labor costs and material waste. Overall, the adoption of automation and robotics in tote bag manufacturing improves productivity, quality, and cost-effectiveness.

4. Challenges and Considerations

While automation and robotics offer significant advantages, there are challenges and considerations to be addressed in tote bag manufacturing. Initial investment costs can be high, requiring businesses to carefully evaluate the return on investment. Additionally, the implementation of automation and robotics may require retraining or upskilling of the workforce to operate and maintain these technologies effectively. Ensuring compatibility between automated systems and existing manufacturing infrastructure is another consideration. Furthermore, the integration of automation and robotics should be balanced with the need for human craftsmanship and customization, as human touch and creativity play a vital role in tote bag design. Striking the right balance between automation and human involvement is crucial to maintain the integrity and uniqueness of custom tote bags.

5. Future Prospects and Industry Trends

The future of tote bag manufacturing lies in the continued development and integration of automation and robotics. Advancements in machine learning, artificial intelligence, and computer vision technologies will further enhance the capabilities of automated systems, enabling them to handle more complex tasks and adapt to changing production requirements. Industry trends also point towards increased customization and personalization options, and automation and robotics will play a key role in meeting these demands efficiently. Moreover, the integration of sustainability practices, such as the use of eco-friendly materials and energy-efficient technologies, will shape the future of automated tote bag manufacturing, aligning with the growing focus on environmental responsibility.

6. Collaboration between Technology and Human Craftsmanship

While automation and robotics bring efficiency and precision to tote bag manufacturing, the collaboration between technology and human craftsmanship remains essential. Human artisans possess the creativity, expertise, and attention to detail required for intricate designs, customization, and quality control. Tote bag manufacturers can leverage automation and robotics to streamline repetitive tasks, allowing artisans to focus on design, product development, and quality assurance. The combination of technology and human craftsmanship ensures that tote bags maintain their unique appeal and artisanal touch, while benefiting from the efficiency and consistency provided by automation and robotics.

Automation and robotics have revolutionized tote bag manufacturing, improving efficiency, productivity, and quality. From automated cutting and sewing processes to robotics in assembly and packaging, these technologies offer numerous benefits. While challenges and considerations exist, the future of tote bag manufacturing lies in the continued integration of automation and robotics. Striking a balance between technology and human craftsmanship is crucial to maintain the uniqueness and customization of tote bags. By embracing automation and robotics, businesses can meet the growing demand for custom tote bags while enhancing productivity, quality, and sustainability in the manufacturing process.

share

Contact Us

Your email address will not be published. Required fields are marked*

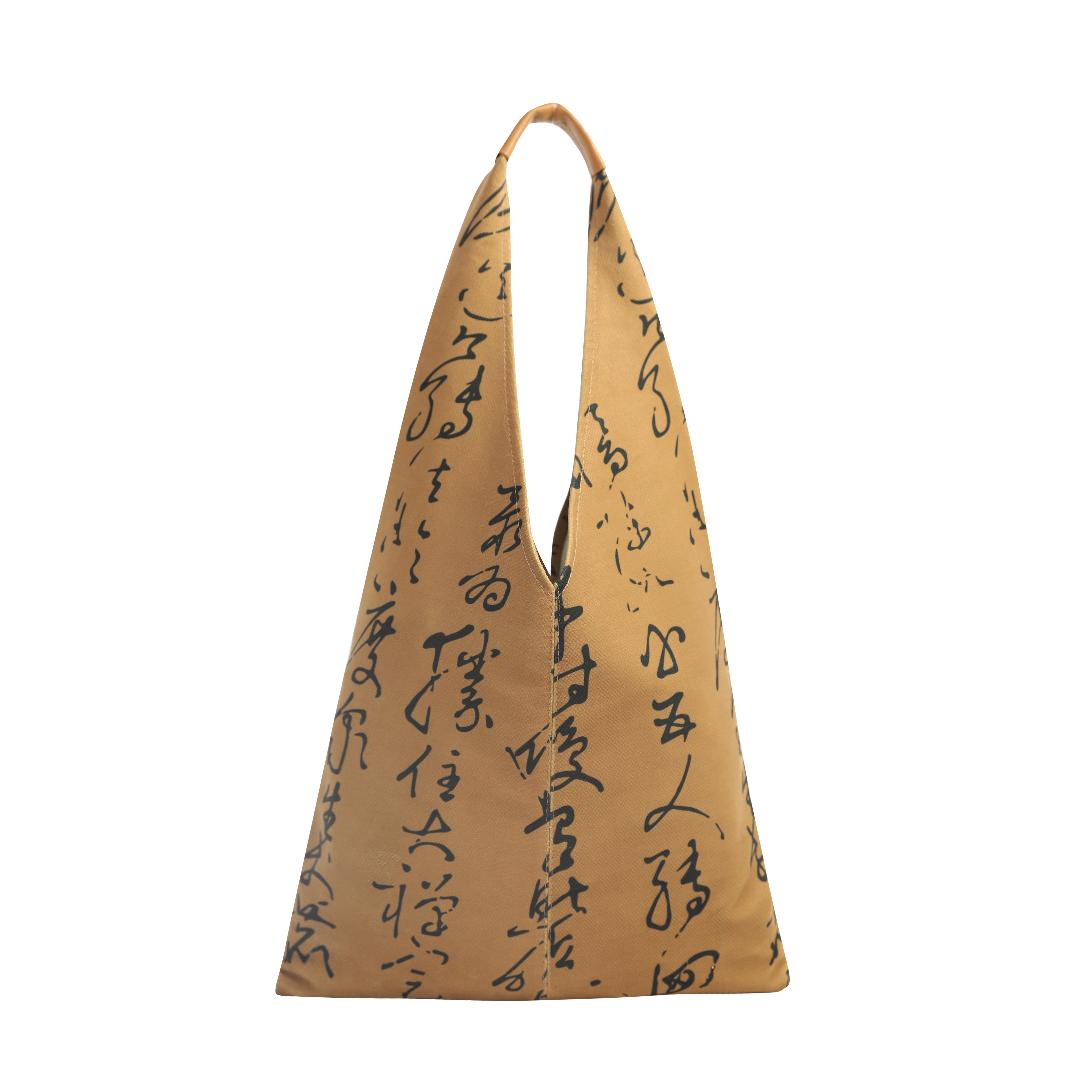

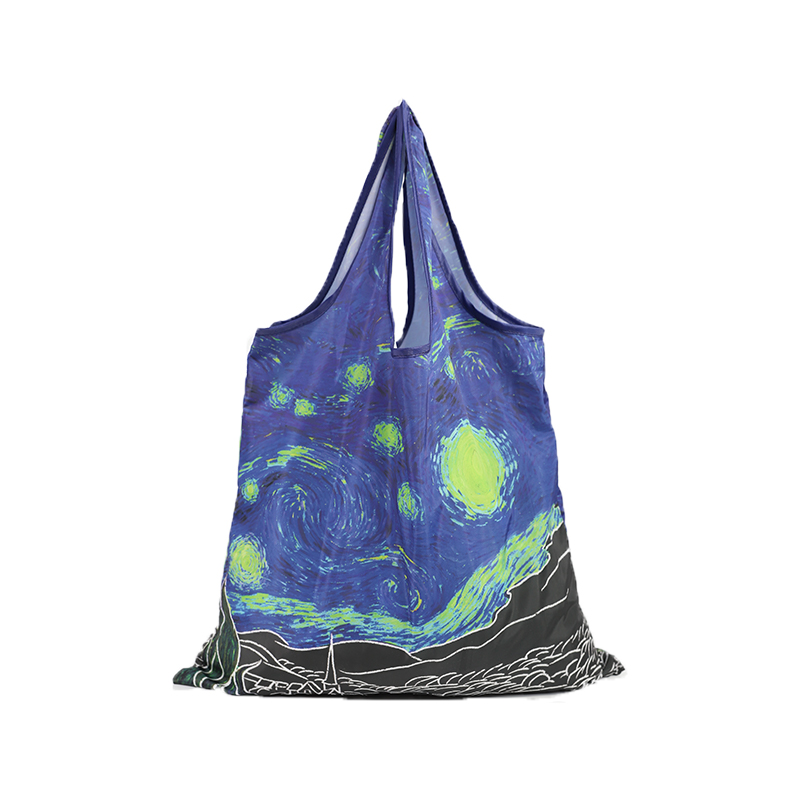

Related Products

© 2024 广东嘉绘美纺织品有限公司 Guangdong Gahumi Textile Co., Ltd | Powered by

Matchpages

Privacy Policy

Sitemap

Contact Us